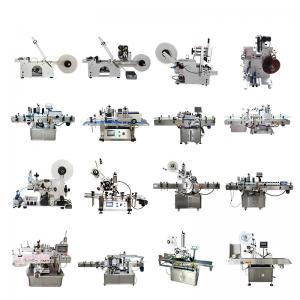

Different types of filling machine

Filling machines are crucial in the packaging industry, allowing for the efficient, accurate, and sanitary bottling of various products. These machines are designed to fill containers with liquids, semi-solids, powders, or solid items, and their designs vary greatly depending on the product's nature, the container's characteristics, and the required production capacity. Here are the primary types of filling machines, each suited for specific filling needs:

1. Liquid Filling Machines

- Volumetric Filling Machines: These machines fill a precise amount of liquid into the container, measured by volume. They are ideal for products where consistent volume is crucial.

- Gravity Fillers: Utilizing gravity, these machines allow the product to flow into the container until it reaches a specific level. They are best suited for thin, free-flowing liquids.

- Pump Fillers: Equipped with pumps to facilitate the filling process, these machines can handle a range of viscosities, from thin liquids to thick creams and pastes.

- Piston Filling Machines: These fillers draw a product into a cylinder and then eject it into the container. They are versatile and can handle a wide range of product viscosities and particulates.

2. Powder Filling Machines

- Auger Fillers: These use a rotating auger to dispense precise amounts of powder into a container. They are ideal for products like spices, flour, or chemical powders.

- Vacuum Fillers: Particularly used for filling bottles or jars with dry powders, they work by creating a vacuum to pull the product into the container.

3. Paste Filling Machines

- Piston Paste Fillers: Designed for viscous products and pastes, these machines use a piston to push the product into the container, ensuring consistent fill volumes.

4. Solid Filling Machines

- Counting Machines: These are used for products that need to be counted and dispensed accurately, such as pills, capsules, or candies.

- Weigh Fillers: These machines fill the container based on weight, using scales to ensure each container reaches the desired weight with high accuracy.

5. Aerosol Filling Machines

- Under-cup Fillers: Used for aerosol products, filling from the bottom and sealing the product under pressure.

- Through-valve Fillers: Fill the product through the aerosol valve in a sealed environment, ensuring no contamination and accurate filling.

6. Specialty Filling Machines

- Custom Fillers: Designed for unique or challenging filling requirements that standard machines cannot meet, tailored to specific product characteristics or container shapes.

Considerations for Choosing a Filling Machine

- Product Viscosity: The thickness of the product determines the type of filling machine, whether it's for liquids, pastes, powders, or solids.

- Container Type: Different machines accommodate various container shapes, sizes, and materials.

- Filling Speed: Production volume requirements dictate the speed and automation level of the filling machine.

- Accuracy Requirements: The precision needed in the filling process can influence the choice of machine, especially in industries like pharmaceuticals and food processing.

Filling machines are integral to packaging lines, ensuring efficiency, accuracy, and product integrity. The right filling machine not only improves production efficiency but also maintains consistent product quality, which is crucial for consumer satisfaction and regulatory compliance.