A Step-by-Step Guide: How to Choose the Right Capping Machine for Your Business

Step 1: Analyze Your Container and Cap

Before you even look at machines, you must thoroughly understand what you're capping.

-

Container Type: What is it made of? (Glass, PET plastic, HDPE, metal). Is it rigid or flexible? What is its height and diameter?

-

Cap Type: This is the most crucial factor. What kind of closure are you using?

-

Screw-On Caps: The most common type. Requires a chuck to grip and spin the cap.

-

Snap-On Caps: Pressed into place. Requires a different, often simpler, mechanism.

-

ROPP (Roll-On Pilfer-Proof): Aluminum caps that are threaded onto the bottle by the machine itself.

-

Corkers: For wine and spirits.

-

Press-On/Turn (Child-Resistant): Requires a push-down and turn motion.

-

-

Torque Requirements: How tight does the cap need to be? Under-tightening causes leaks; over-tightening can damage the container or cap, or make it impossible for the end-user to open. You need a machine that offers precise, adjustable torque control.

Step 2: Evaluate Your Production Needs

The scale and speed of your operation will dictate the level of automation you require.

-

Throughput (Bottles Per Minute - BPM): How many containers do you need to cap per minute or per hour? This is your primary driver.

-

Low Speed (<30 BPM): A manual benchtop capper or a semi-automatic model may be sufficient.

-

Medium Speed (30-120 BPM): A single-head automatic capper integrated into your line is typically the solution.

-

High Speed (120+ BPM): You'll likely need a multi-head rotary capper capable of handling multiple containers simultaneously.

-

-

Line Space: How much physical space do you have for the capping machine? In-line systems are long and narrow, while rotary systems have a larger footprint.

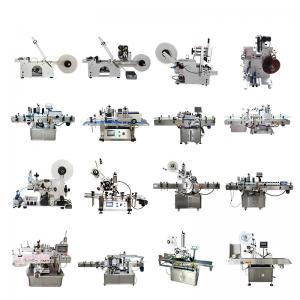

Step 3: Understand the Different Types of Capping Machines

-

Manual Benchtop Cappers: Ideal for R&D, low-volume production, or pilot batches. Operated by hand, they are affordable but labor-intensive.

-

Semi-Automatic Cappers: The operator places the container and cap, and a foot pedal or button activates the capping mechanism. A good middle ground for small to medium batches.

-

Automatic In-Line Cappers: These are workhorses for production lines. Containers are fed in a single file, and the machine automatically applies and tightens the caps. They can be chuck-style (spinning the cap) or spindle-style (spinning the container).

-

Automatic Rotary Cappers: Designed for very high-speed operations. Containers move in a circle while multiple capping heads apply caps simultaneously. This is the choice for large-scale beverage, pharmaceutical, or chemical plants.

Step 4: Consider Key Technical Features

Don't just buy a basic machine; ensure it has the features you need for quality and flexibility.

-

Torque Control: Look for a machine with an easily adjustable and reliable torque system (e.g., magnetic clutch, servo drive). Servo-driven cappers offer the highest precision and programmability for different products.

-

Changeover Ease: If you run multiple products with different container or cap sizes, how quickly and easily can you change the parts (chucks, grippers, height adjustments)? Quick-change tooling is a massive time-saver.

-

Cap Handling & Feeding: Will you be placing caps by hand, or do you need an automatic cap feeder (a cap elevator)? An automated feeder drastically increases speed and reduces labor.

-

Construction & Hygiene: Is the frame sturdy and vibration-resistant? Are the parts in contact with your product (contact parts) made of stainless steel or other sanitary, easy-clean materials? This is non-negotiable for food, pharmaceutical, and cosmetic applications.

-

Integration & Controls: Can the machine easily communicate with your upstream and downstream equipment (fillers, labelers)? Is the control panel (often an HMI - Human-Machine Interface) user-friendly?

Step 5: Plan for the Future and Partner Wisely

-

Scalability: Consider not just your current needs, but where you want to be in 3-5 years. Can the machine be upgraded or reconfigured to handle higher speeds or different products?

-

Supplier Reputation & Support: This is paramount. Choose a manufacturer or distributor known for quality machinery and, just as importantly, exceptional after-sales support. Ask about:

-

Availability of spare parts.

-

Technical support and service response time.

-

Installation, training, and warranty.

-

Checklist: Your Capping Machine Decision Matrix

| Factor | Your Requirement |

|---|---|

| Cap Type | (e.g., 28mm Screw Cap) |

| Container | (e.g., 500ml PET Round Bottle) |

| Target Torque | (e.g., 10-12 in-lbs) |

| Speed (BPM) | (e.g., 60 BPM) |

| Automation Level | (e.g., Automatic In-Line) |

| Cap Feeding | (e.g., Required - Cap Elevator) |

| Changeover Frequency | (e.g., Daily - Need Quick-Change) |

| Industry Hygiene | (e.g., Food-Grade, 304SS Contact Parts) |

| Budget | (e.g., $XX,XXX) |

| Preferred Suppliers | (e.g., Manufacturer A, Distributor B) |

Final Thought:

A capping machine is a long-term investment in your brand's consistency and reliability. Taking the time to methodically evaluate your requirements will prevent costly mistakes and ensure the machine you choose becomes a seamless, productive part of your operation for years to come. Don't hesitate to request product trials or factory tests with your specific containers—a reputable supplier will be happy to oblige.